THE SCOPE

What do I need?

Each of our clients work with different materials under a broad range of environmental and loading conditions. One common thread is that our customers are looking to characterize their materials to gain greater insight in design, testing, modeling and/or simulating their materials. The most important testing requirements K&C’s laboratory staff need to understand in order to characterize a material or materials of interest include:

Stress state (What are the stress states of interest? Compression, tension, shear, confined, etc.)

Temperature (K&C can test at temperatures as low as -100 degrees up to 1000 degrees celsius)

Strain Rate (K&C can test a broad range of strain rates from quasi-static up to 1E6/s, or more for special cases)

Phenomenology (What is your objective? Elastic properties, plastic (e.g., stress-strain), failure, fracture, shock, or fragmentation characterization?)

EQUIPMENT & CUSTOM APPARATUSES

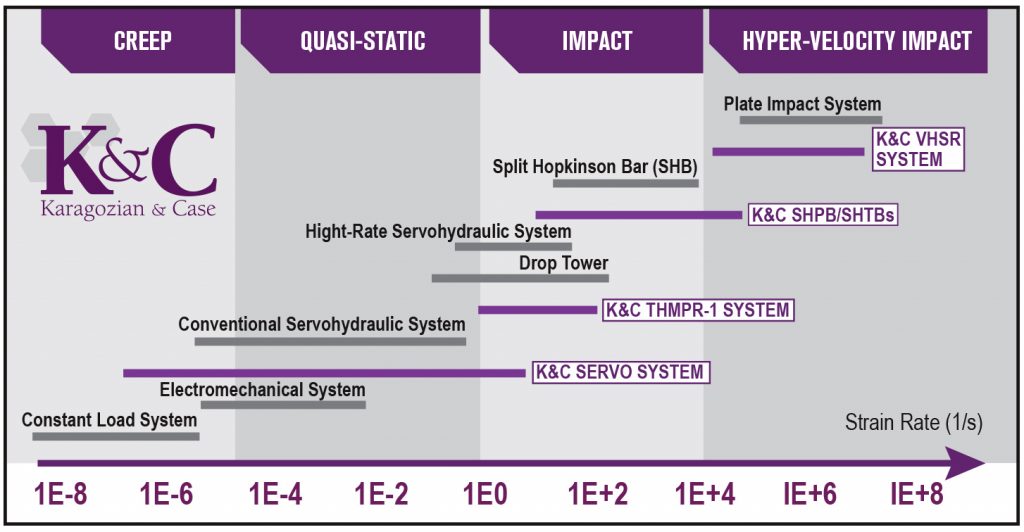

Given each client’s requirements in these categories, K&C staff can quickly identify one or more of K&C’s test setups that can be used to measure and obtain the experimental data that can be used to characterize the material. The table below illustrates the various equipment and custom apparatuses K&C uses for testing.

Various Equipment and Custom Apparatuses K&C uses for Testing

The Process

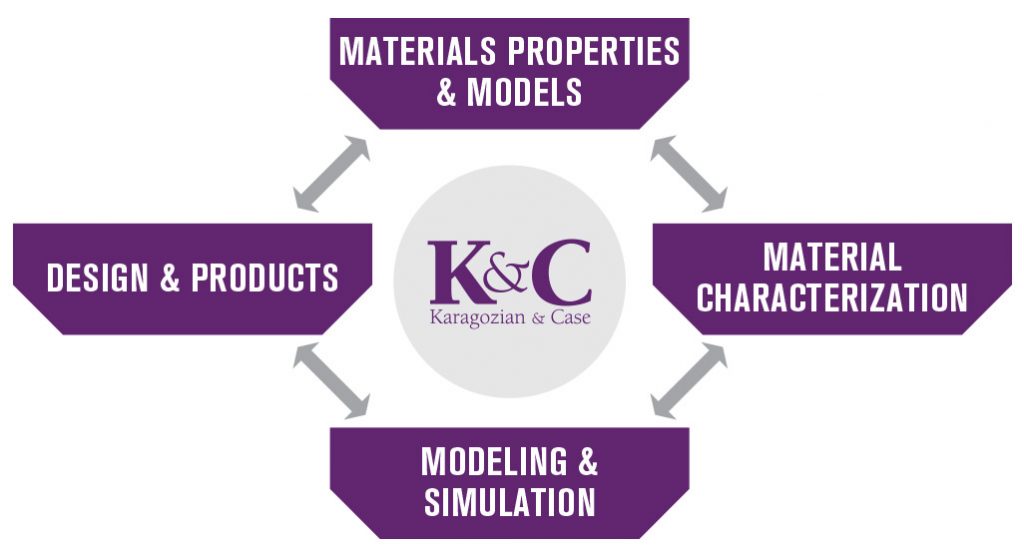

Why is material characterization so valuable to designing or modeling your materials?

Customers are increasingly needing to identify new, and push existing, materials for new products in extreme conditions and need material selection approaches, design methods, and modeling approaches that hinge on accurate material characterization data. The material characterization data K&C will generate for a specific material, environmental conditions, and loading regime can then be used directly in the client’s design, analysis processes, or to assess or improve their material candidates. If desired K&C can also provide modeling and simulation services. Regardless of the analysis or modeling, the newly characterized material data will add highly valuable input to your projects at a relatively small cost when compared to the life cycle cost of your product. Utilizing standard material models and off-the-shelf parameters from a reference generated decades ago can lead to poor and even erroneous results. Maximize your projects by getting accurate dynamic material characterization data!

Methods

How will my materials be tested?

The method of testing will greatly depend on the material and test conditions of interest. K&C currently operates several test apparatuses that can be used for our dynamic material characterization experiments including:

Quasi-static servo-controlled systems

Miniaturized systems

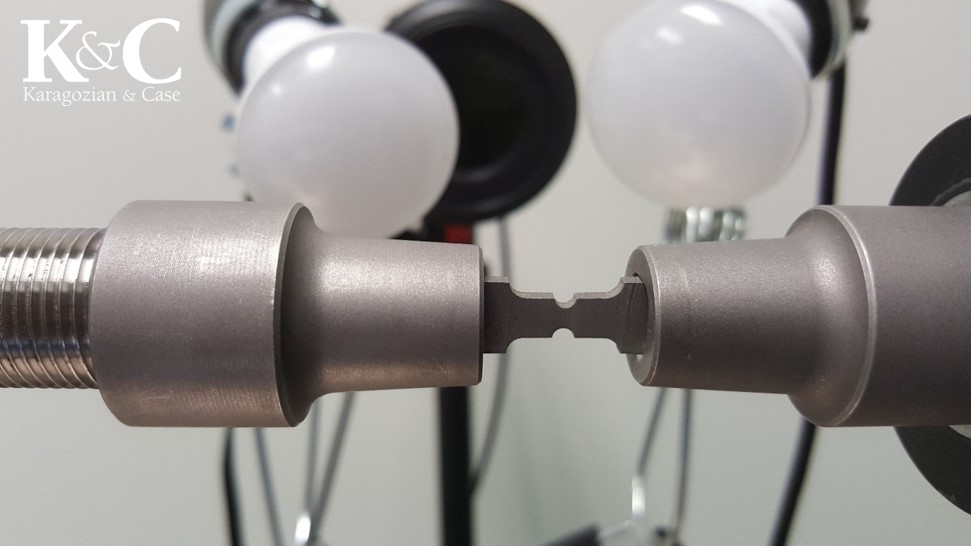

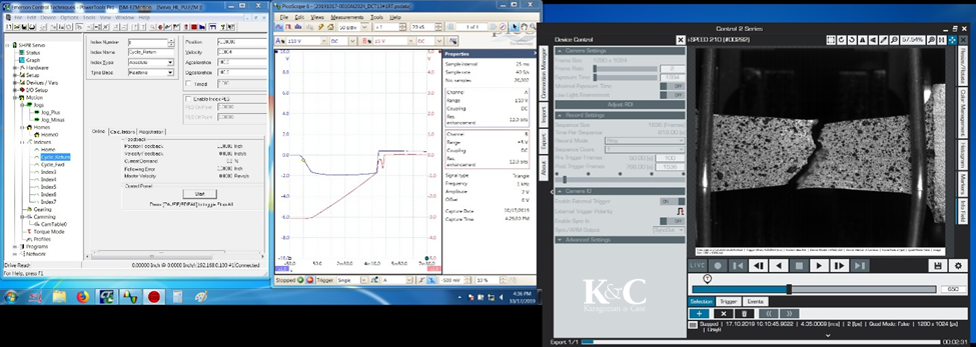

Tensile Test on K&C’s Servo System

Depending on the apparatus and test setup selected for your project, K&C will utilize advanced instrumentation, measurement, and data acquisition system to obtain the data needed to meet your needs. This includes:

Strain Gages

Spring-mounted extensometers

Laser-based velocimeters

Laser-based extensometers

High-speed video up to 1,000,000 fps

High-speed lighting systems

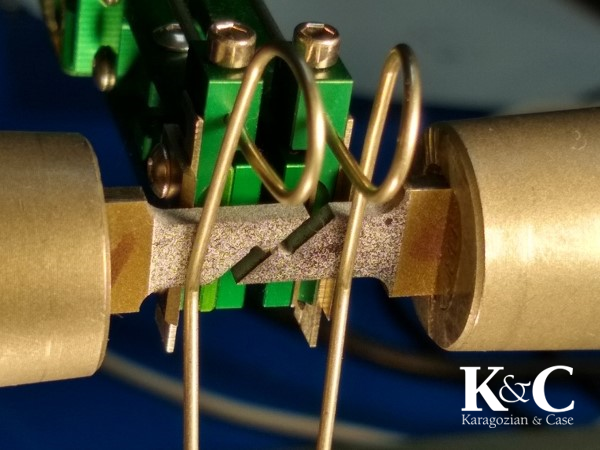

High Temperature Shear Test on Alloy Steel Sample

Data Acquisition from Tensile Test

MATERIALS AND/OR TEST SPECIMENS

Do I need to provide the material/test specimen?

K&C generally considers at least two options based on a customer’s needs: (1) the customer can choose to machine and prepare the samples according to K&C specifications; or (2) K&C can provide a turnkey solution for the machining of the test specimens given the raw materials are provided or prescribed by the customer.

Machining Sample from Stock Plate

DELIVERABLES

What will I receive after the tests are completed?

Depending on the customer’s requirements, the following deliverables can be provided:

- K&C will provide the test data in text or CSV format with a brief letter summarizing the data files.

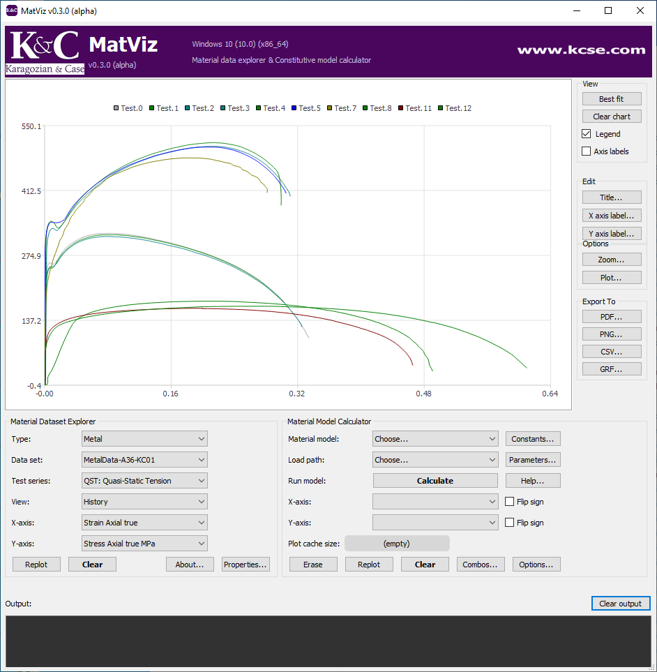

- The data can also be encapsulated in a binary database for plotting with K&C’s MatViz software solution.

- A detailed test report.

- Detailed full-field strain field data for failure analysis or validation with computational models.

ADDITIONAL OPTIONS

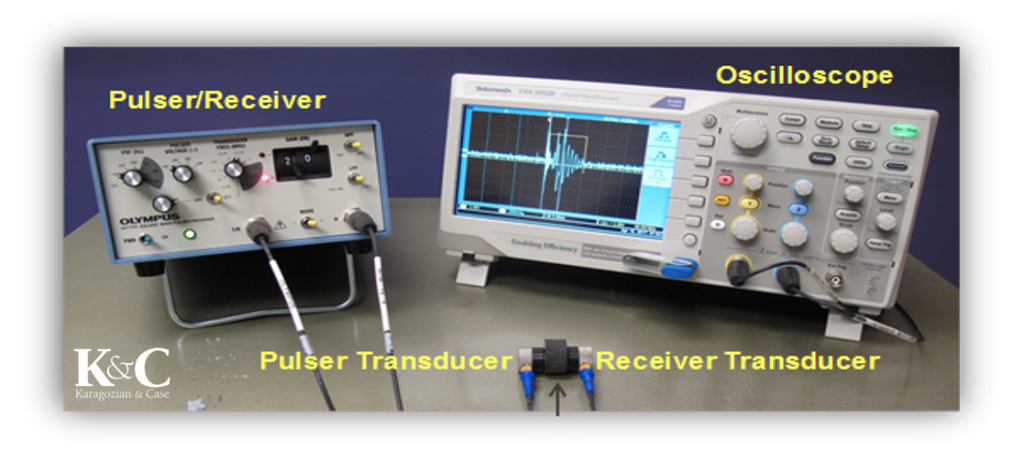

- Non-Destructive Evaluation or Testing experiments, which are useful for confirming elastic properties for materials can be included.

- High-Speed Video (HSV) of the tests can be included.

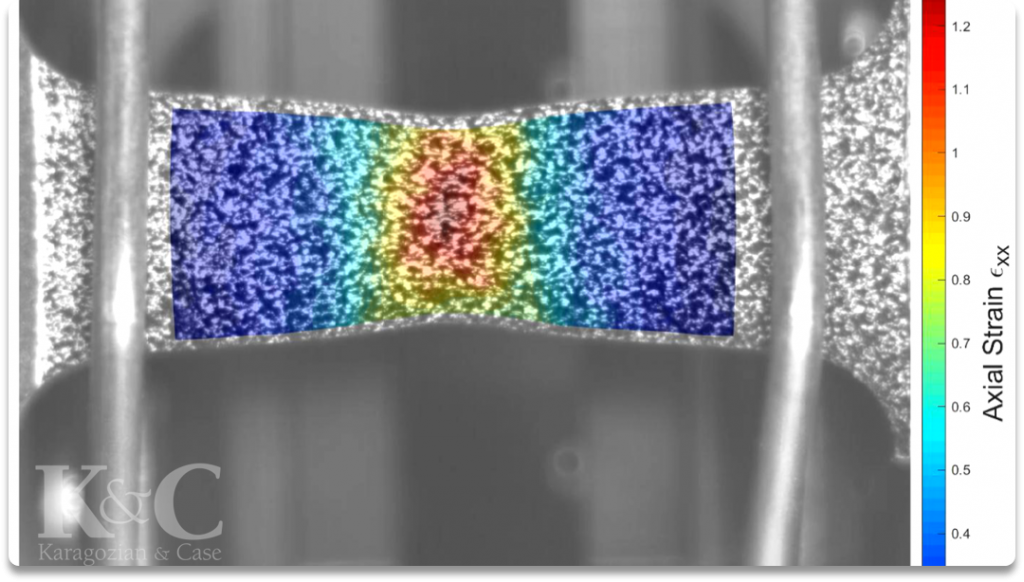

- Digital Image Correlation (DIC) analysis of any imagery can be included, which is useful for obtaining failure properties.

- Derived material constitutive parameters for advanced finite element analysis (FEA)

- CT scanning of pristine or damage specimens

Detailed Test Report

K&C’s Software MatViz – A Material Data Explorer and Constitutive Model Calculator

Non-Destructive Evaluation Equipment

Digital Image Correlation illustrating strain profile on steel tension specimen

Checkered paint specimen in K&C’s THMPR high-strain test equipment

FINITE ELEMENT ANALYSIS & MATERIAL PARAMETERS

Can K&C develop material parameters for my material and do the FEA computations?

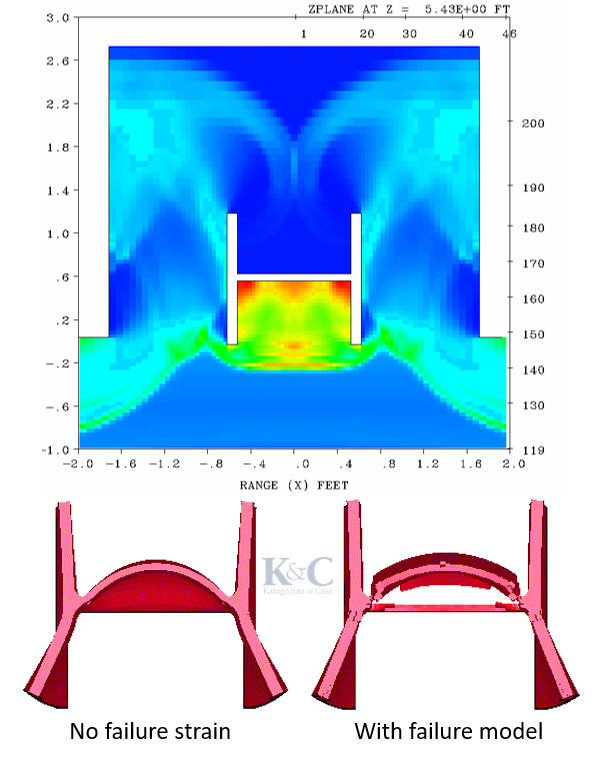

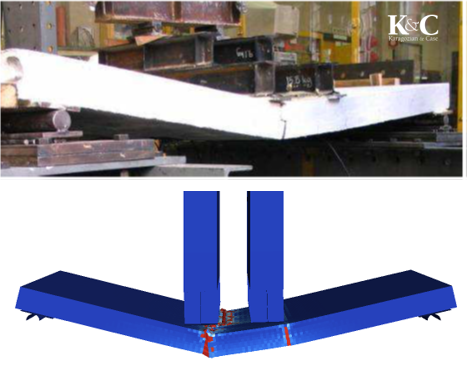

Yes, K&C supports clients with developing material parameters that customers can then use directly in their own FEA computations. Additionally, if the client prefers K&C can complete any number of FEA computations, below are a few example FEA computations.

Fractured structural column from a blast test

Compressible CFD analysis (top) and structural FEA for the column response (bottom)

Structural FEA comparative of a four-point bending test on a brittle structure.

NEXT STEP

How do I get a quote or ask questions?

Hopefully, the above section was informative. If you would like to receive a quote for any of these services please click below. If you have any immediate questions please call K&C’s main number at 818-240-1919 and you will be routed to an engineer that is best suited for your area of interest.